Understanding the Kiln Process for Sintering Active Battery Materials

by Therser Sales Team on 31-May-2023 16:05:04

The production of high-performance batteries relies on various manufacturing processes, and one essential step is the kiln process for sintering active battery materials. Sintering involves heating powdered battery materials to enhance their properties and promote particle bonding. In …

A 6 Step Comprehensive Guide to Investing in a New Industrial Kiln

by Therser UK on 31-May-2023 15:26:04

Investing in a new industrial kiln is a significant decision that requires careful consideration of several factors. From understanding your specific requirements to evaluating energy efficiency and safety considerations, each step plays a crucial role in selecting the right kiln for …

Gas vs. Electric Kilns: Choosing the Right Power Source for Your New Kiln

by Therser UK on 31-May-2023 15:15:39

Investing in a new kiln is an exciting step for any business. However, before diving into the world of firing, there's a crucial decision to make: the power source for your kiln. Gas and electric kilns are the two primary options available, each with their own merits and drawbacks. In …

Are kilns electric or gas?

by Therser UK on 30-May-2023 14:28:11

Electric kilns are powered by electricity and use heating elements to generate heat. These elements are made of materials such as kanthal or nichrome, which can withstand high temperatures without breaking down. The elements are placed inside the kiln and are wired to a controller, wh …

Battery Show Europe 2023 - Last Day

by Therser UK on 25-May-2023 09:09:27

What a week we have had @ The Battery Show Europe 2023.

Therser UK's Stand is Now Open

by Therser UK on 23-May-2023 08:43:36

Therser UK's third time at the Europe Battery Show.

Shaping the Future of Battery Material Production

by Therser UK on 19-May-2023 10:59:00

Shaping the Future of Battery Material Production: The Ultimate Guide

Mastering the Art of Firing Anode and Cathode Battery Materials in Kilns

by Therser UK on 19-May-2023 10:13:30

Mastering the Art of Firing Anode and Cathode Battery Materials in Kilns The manufacturing process of battery materials involves a crucial step known as firing, where anode and cathode precursors undergo controlled high-temperature treatment to enhance their structural integrity and o …

Therser UK at the Cutting Edge of Protective Atmosphere Control Kilns.

by Therser Sales Team on 18-May-2023 11:19:58

Here at Therser UK we at the forefront of innovation, new cutting edge technologies and standards.

How Many Different Products Use Heat Treatment Systems in their Manufacture? You Would Be Surprised!

by Therser UK on 18-May-2023 11:19:00

In simple terms, heat treatment is the process of heating metal holding it at a certain temperature, then cooling it. During this process the metal will undergo changes in its properties. There will be many different changes that can be done, these can be determined by how long the me …

Therser UK and The Future Of Battery Materials - With Free Guide

by Therser UK on 18-May-2023 11:17:58

Download our Free Guide to Battery Materials here https://blog.therseruk.com/battery-materials-shaping-the-future-guide Lithium-Ion batteries have a much higher limitation of energy and power in comparison to other batteries, making it the technology of choice for all kinds of differe …

Therser UK is @ The Battery Show Stuttgart 2023

by Therser Sales Team on 18-May-2023 11:16:04

We are proud to announce Therser UK will be taking part once again in The Battery Show Europe , 23-25 MAY, 2023 Messe Stuttgart Stuttgart, Germany. Therser UK are excited to be attending for the third year running. Therser will have their own stand at the expo, the stand will be found …

What is the best kiln for battery material production?

by Therser UK on 18-May-2023 10:41:50

One of the most important tasks that contemporary roller kilns are put to is the development of lithium-ion battery cathode and anode materials. Research and development departments in battery production use roller kilns to make new prototypes which are ever more efficient.

Therser UK at The Battery Show Europe.

by Therser UK on 18-May-2023 10:40:52

Therser UK will be taking part once again in The Battery Show Europe. Located in Stuttgart, Germany Therser UK are excited to be attending for the second year running. Therser will have their own stand at the expo, the stand will be found at number 6-D20, this is where the team will b …

Therser UK Create Battery Materials Animations

by Therser UK on 18-May-2023 10:38:38

Therser UK would like the opportunity to introduce our new kiln/automation videos available now on our YouTube channel called 'Therser UK'

Therser UK at Battery Show Europe Hall 8 stand 220

by Therser UK on 18-May-2023 10:37:27

Therser UK are at the Battery Show Europe in Stuttgart, Germany from the 30th of November to the 2nd of December and can be found at hall 8 stand 220.

Therser UK Offers Guide On Their Battery Material Products.

by Therser UK on 18-May-2023 10:35:21

Therser UK have created a guide for Battery Materials, in the battery materials guide Therser UK talk about topics such as the following;

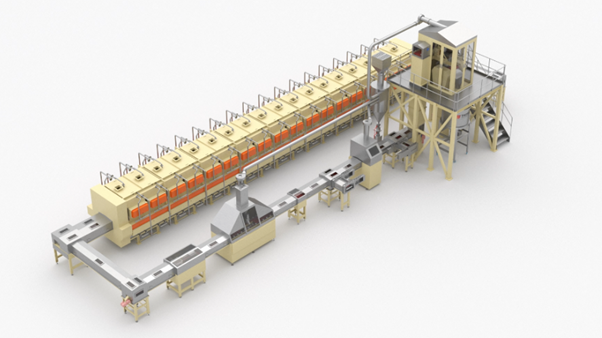

What is a Pusher Furnace

by Therser Sales Team on 11-May-2023 15:33:30

A Pusher Furnace, also known as a Pusher-Type Furnace, is a type of industrial furnace used for continuous heat treatment processes, typically in high-volume production settings. It is designed to handle a continuous flow of workpieces or materials, pushing them through the furnace fo …

What is a Pit Furnace

by Therser UK on 11-May-2023 15:30:47

Pit Furnace, also known as a Pit-Type Furnace, is a type of industrial furnace that is designed to be installed in an excavated pit or depression in the ground. It is commonly used for various heat treatment processes, such as tempering, annealing, and carburizing of metal components.

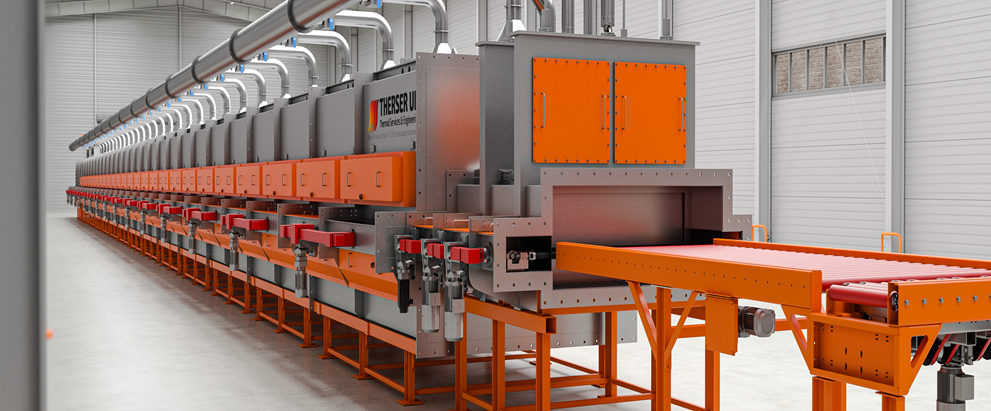

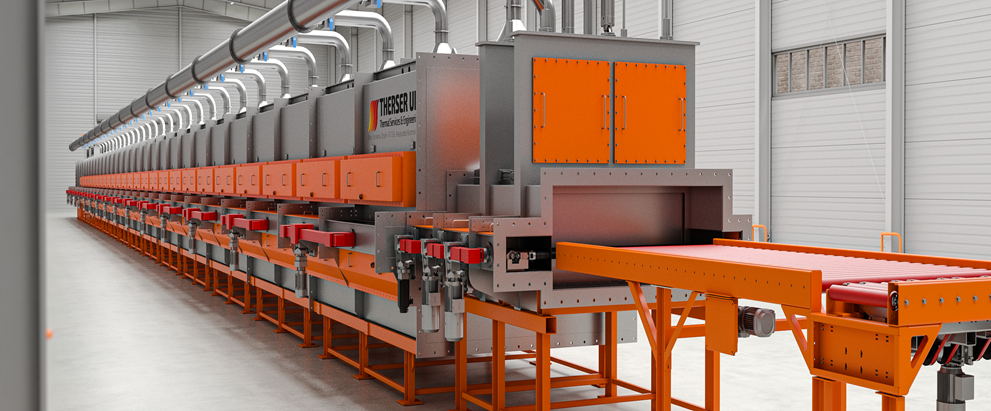

What is a Mesh Belt Furnace

by Therser Sales Team on 11-May-2023 15:26:38

A Mesh Belt Furnace, also known as a Mesh Belt Conveyor Furnace, is a type of continuous industrial furnace commonly used for various heat treatment processes, such as sintering, brazing, annealing, and drying. It is designed to convey workpieces or materials through the furnace on a …

What is a Elevator Furnace

by Therser UK on 11-May-2023 15:24:03

An Elevator Furnace, also known as a Vertical Lift Furnace or Elevator Hearth Furnace, is a type of industrial furnace that employs a vertical lift mechanism to transport workpieces or materials through the heating and cooling processes. It is commonly used for various heat treatment …

What is a Bogie Hearth Furnaces

by Therser UK on 11-May-2023 15:21:30

A Bogie Hearth Furnace, also known as a Bogie Furnace or Bogie Hearth Oven, is a type of industrial furnace commonly used for various heat treatment processes, such as annealing, tempering, stress relieving, and brazing of metal components. It is particularly suitable for large and he …

What is a Walking Beam Furnace

by Therser UK on 11-May-2023 15:18:53

A Walking Beam Furnace is a type of continuous furnace commonly used for various high-temperature heat treatment processes, particularly in the steel industry. It is designed to transport and heat large, heavy, or elongated workpieces, such as steel billets, slabs, or bars, through th …

What is a Seal Quench Furnace

by Therser UK on 11-May-2023 09:13:50

A Seal Quench Furnace, also known as a Sealed Quench Furnace, is a type of heat-treating furnace commonly used in the manufacturing and processing of various metal components. It is primarily employed for the heat treatment of steel parts to achieve desired mechanical properties and e …

What is a Lift Off Furnace (Top Hat)

by Therser Sales Team on 11-May-2023 09:05:12

A Lift Off Furnace, also known as a Top Hat Furnace, is a type of industrial furnace used for various high-temperature processes, particularly in the steel industry. It is designed to heat and melt materials, such as metal scraps or alloys, in a controlled environment.

What is a Rotary Hearth Furnace

by Therser Sales Team on 11-May-2023 08:33:28

Rotary Hearth Furnace (RHF)

What is Case Hardening?

by Therser Sales Team on 10-May-2023 09:17:23

Case Hardening: Case hardening is a heat treatment process used to increase the surface hardness of materials by adding a thin layer of a harder material to their surface. This process involves heating the material in a carbon-rich atmosphere, such as carbon monoxide or methane. Case …

What is Normalizing

by Therser Sales Team on 10-May-2023 09:16:43

Normalizing: Normalizing is a heat treatment process that involves heating a material to a specific temperature and then cooling it in still air. This process is used to improve the mechanical properties of materials by refining their grain structure. Normalizing can improve the tough …

What is Solution Treatment?

by Therser UK on 10-May-2023 09:15:47

Solution Treatment: , making them more pure and homogeneous. This process involves heating the material to a specific temperature and then cooling it rapidly. Solution treatment can improve the strength, ductility, and corrosion resistance of materials, making them more suitable for d …

What is Nitriding?

by Therser UK on 10-May-2023 09:13:27

Nitriding: Nitriding is a heat treatment process used to increase the surface hardness and wear resistance of materials by diffusing nitrogen into their surface. This process involves heating the material in an ammonia-rich atmosphere. Nitriding can improve the fatigue resistance and …

What is Spheroidizing

by Therser UK on 10-May-2023 09:11:07

Spheroidizing: Spheroidizing is a heat treatment process used to improve the machinability and ductility of materials. This process involves heating the material to a specific temperature and holding it there for a period of time to encourage the formation of spherical carbides. Spher …

What is Austempering?

by Therser UK on 10-May-2023 09:09:10

Austempering: Austempering is a heat treatment process used to improve the toughness and ductility of materials. This process involves heating the material to a specific temperature, holding it there for a period of time to ensure even heating, and then rapidly cooling it in a quenchi …

What is Martempering

by Therser UK on 10-May-2023 09:06:27

Martempering: Martempering, also known as quenching and tempering, is a heat treatment process used to improve the strength, toughness, and wear resistance of materials. This process involves heating the material to a specific temperature, holding it there for a period of time to ensu …

What is Quenching?

by Therser UK on 10-May-2023 09:02:07

Quenching: Quenching is a heat treatment process used to harden materials by rapidly cooling them down from a high temperature to room temperature. This process can be done in various mediums, such as water, oil, or air. Quenching can increase the strength and wear resistance of mater …

What is annealing?

by Therser UK on 10-May-2023 08:52:26

Annealing: Annealing is a heat treatment process used to soften materials, improve ductility, and relieve internal stresses. The annealing process can be performed in various atmospheres, such as vacuum, inert gas, or air. The purpose of annealing is to make a material more workable b …

What is the difference between an regenerative thermal oxidizer and an afterburner?

by Therser UK on 09-May-2023 10:31:51

Regenerative Thermal Oxidizer (RTO): An RTO is an advanced air pollution control system used to treat and eliminate volatile organic compounds (VOCs), hazardous air pollutants (HAPs), and other harmful airborne contaminants emitted by industrial processes. The main objective of an RTO …

What is Debinding?

by Therser UK on 09-May-2023 09:37:34

Debinding, also known as solvent extraction or removal of binders, is a process used in powder metallurgy and other manufacturing techniques involving the use of binders or additives. It involves the removal of organic materials, such as binders, lubricants, or additives, from a green …

What is Tempering?

by Therser Sales Team on 09-May-2023 09:33:54

Tempering is a heat treatment process applied to metals, typically steel, to improve its mechanical properties. It involves heating the metal to a specific temperature and then cooling it in a controlled manner. The purpose of tempering is to reduce the brittleness of the material whi …

What is Carbonization?

by Therser Sales Team on 09-May-2023 09:25:53

Carbonization is a process that involves the decomposition or transformation of organic materials, typically rich in carbon, into carbon-rich solid residues. It occurs through the application of heat in the absence or limited supply of oxygen. The process removes volatile components, …

What is the use of a furnace?

by Therser UK on 03-May-2023 10:07:53

A furnace is a type of heating device that is used to generate heat or to carry out high-temperature processes. It is commonly used in industries that require high temperatures, such as metalworking, glass manufacturing, and chemical processing. In this article, we will explore the us …

What is the use of a kiln?

by Therser UK on 03-May-2023 10:04:13

but its primary use is for firing clay and ceramic objects. Kilns have been used for thousands of years, and they have evolved over time to become highly specialized tools used in a wide range of industries.

What is the best kiln for tableware?

by Therser UK on 03-May-2023 09:59:19

When it comes to firing tableware, it's important to consider several factors when choosing a kiln. The most important consideration is safety, both for the maker and for the end user of the tableware. Additionally, you want to ensure that the kiln you choose is appropriate for the ty …

What Is The Best Kiln For Ceramics

by Therser Sales Team on 03-May-2023 09:56:24

Electric Kilns: Electric kilns are powered by electricity and use heating elements to produce heat. They are easy to use, as you simply plug them in and set the temperature. Electric kilns are ideal for low-fire and mid-range firing, which is when ceramics are fired at temperatures be …

What is the difference between welding and fabrication?

by Therser Sales Team on 02-May-2023 14:55:33

Welding is a specific technique used to join two pieces of metal together. It involves heating the metal to its melting point using a variety of methods, including gas flames, electric arcs, or laser beams. Once the metal is melted, a filler material is added to the joint to help fuse …

What certificates does a company need to do fabrication?

by Therser Sales Team on 02-May-2023 14:42:36

Welding certifications: If a fabrication company performs welding, it may need to obtain certifications for specific welding processes and techniques. These certifications demonstrate that the welders are proficient in the specific welding process and technique being used. Welding cer …

What type of welding is the best for my application?

by Therser UK on 02-May-2023 14:22:19

There is no one "best" type of welding as each type has its own advantages and disadvantages depending on the application and materials being welded. Some factors to consider when selecting a welding method include the type and thickness of the material, the desired strength and quali …

What type of fabrication do I need?

by Therser UK on 02-May-2023 14:17:40

Welding: Welding is a process of joining two or more pieces of metal together using heat and/or pressure. The heat can be generated by a flame, an electric arc, or a laser. Welding can be used to create structures, repair damaged components, or add additional material to existing comp …

What is the process of Alloy Fabrication?

by Therser Sales Team on 02-May-2023 11:06:29

Alloy Fabrication