Share this

Mastering the Art of Firing Anode and Cathode Battery Materials in Kilns

by Therser UK on 19-May-2023 10:13:30

Mastering the Art of Firing Anode and Cathode Battery Materials in Kilns

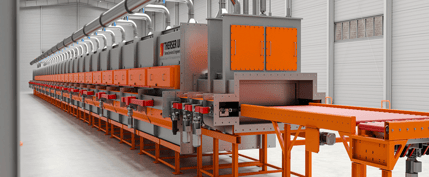

The manufacturing process of battery materials involves a crucial step known as firing, where anode and cathode precursors undergo controlled high-temperature treatment to enhance their structural integrity and optimize electrochemical properties. Kilns, the workhorses of this process, play a pivotal role in providing the necessary controlled and uniform heat distribution. In this article, we delve into the intricacies of firing anode and cathode battery materials, exploring the significance of kilns and the step-by-step process required to achieve optimal results.

Stage of firing. The anode is carefully placed inside the kiln, which provides a controlled high-temperature environment. As the kiln's heating elements generate intense heat, the temperature is raised to the required level. During this sintering process, the anode material particles fuse together, creating strong interparticle bonds. This bonding improves electrical conductivity and enhances the overall structural integrity of the anode. Once the desired sintering is achieved, the kiln is gradually cooled to room temperature to prevent thermal shock and maintain the stability of the anode material.

Cathode Material Firing Process: Similar to anode materials, the firing process for cathode materials involves several key steps. Cathode precursor materials, such as lithium cobalt oxide (LiCoO2), lithium iron phosphate (LiFePO4), or nickel manganese cobalt oxide (NMC), are processed and mixed with binders and conductive additives to form a slurry. This slurry is then coated onto a current collector, creating the cathode electrode.

The coated cathode electrode undergoes a drying process to remove solvents and ensure the stability of the cathode structure. Subsequently, the cathode is placed inside the kiln, where controlled high temperatures are applied. The kiln's heat triggers a chemical reaction, transforming the cathode material into the desired crystal structure. This sintering process enhances the cathode's electrochemical performance. Gradual cooling in the kiln maintains the integrity of the cathode material, preventing thermal stress and ensuring its stability.

Kiln Technology in Battery Material Firing: The technology employed in kilns for firing battery materials has evolved significantly. Precise temperature control is a critical feature of modern kilns, enabling operators to set and maintain specific firing temperatures, optimizing the sintering process. Atmosphere control is another important aspect, where kilns can operate under controlled atmospheres to prevent undesired chemical reactions and ensure the desired material properties. Kilns are designed to distribute heat uniformly, minimizing temperature variations within the kiln chamber, thanks to efficient insulation materials and carefully engineered heating elements. To ensure safe operation, kilns are equipped with sensors and safety mechanisms, monitoring temperature, pressure, and other parameters.

Common Challenges and Solutions: While firing battery materials in kilns is highly effective, certain challenges may arise during the process. Particle agglomeration, thermal stress, surface reactions, and kiln maintenance are common issues that manufacturers must address. Proper mixing techniques, suitable binders, controlled heating and cooling rates, optimized firing conditions, and regular kiln inspection and cleaning are among the solutions to overcome these challenges.

Best Practices for Firing Battery Materials: Adhering to best practices is crucial for achieving optimal results in firing battery materials. Determining the optimal firing temperatures for specific materials, establishing appropriate time-temperature profiles, ensuring uniform heat distribution, and controlling cooling rates to minimize thermal stress are key considerations.

Advanced Kiln Techniques: Advancements in kiln technology have introduced new techniques for firing battery materials. Vacuum firing reduces oxidation and enhances material purity. Controlled atmosphere firing allows for customized gas environments. Rapid thermal processing shortens firing cycles, and in-situ monitoring provides real-time data for process control.

Quality Control and Testing: To maintain high-quality standards, rigorous quality control and testing methods are employed. Material characterization, electrochemical performance evaluation, microstructural analysis, and safety testing are crucial steps in assessing the properties and reliability of fired battery materials.

Future Trends in Kiln Technology: The future of kiln technology holds promising advancements. Energy efficiency improvements, enhanced temperature control, integration of artificial intelligence for advanced process optimization, and scale-up and automation to increase production capacity are among the anticipated trends.

Conclusion: Kilns are indispensable in the firing process of anode and cathode battery materials, providing the controlled heat required for achieving the desired material properties. Understanding the firing process, employing the best kiln practices, addressing challenges, and embracing advanced techniques contribute to the production of high-quality battery materials. With the continuous evolution of kiln technology, the journey towards efficient and reliable energy storage solutions is propelled forward.

Please contact us for all your testing requirements, Hydrogen, Nitrogen Atmosphere or changing your kiln furnace from Gas to Electric, we do it all!

Do call Therser today for an introductory chat with one of our experts and a no-obligation assessment of your requirements. Call us today on +44 (0) 1782 824453 or use our contact form

Share this

- Company News (90)

- Battery Materials (41)

- kiln (37)

- fabrication (29)

- Alloy (27)

- Furnace (27)

- Welding (16)

- Industrial Kilns (15)

- Battery (13)

- Ceramic Kilns (13)

- Processes (13)

- alloy fabrication (13)

- Shuttle Kilns (12)

- RTO’s (11)

- Vacancies (11)

- Hydrogen (10)

- Therser UK (9)

- Tunnel Kiln (9)

- Refractory (8)

- Therser (8)

- Wellman Furnaces (8)

- Brickwork (7)

- Case Studies (7)

- Afterburners (6)

- Fibre Lining (6)

- electric (6)

- Almor Wellman (5)

- thermal engineers (5)

- Biochar (4)

- Exhibition (4)

- Pyrolysis (4)

- Servicing (4)

- Spares (4)

- heat treatment (4)

- History (3)

- Ceramics Uk (2)

- Combustion Control Upgrades (2)

- Nitrogen (2)

- Temperature Control Rings (2)

- gas (2)

- Certificates (1)

- Instrumentation (1)

- MMC (1)

- RHK (1)

- Roller Hearth Kiln (1)

- Test Trials (1)

- aerospace (1)

- analyser (1)

- elec (1)

- oxygen (1)

- vans (1)

- September 2025 (2)

- May 2025 (2)

- March 2025 (1)

- February 2025 (2)

- January 2025 (5)

- December 2024 (5)

- November 2024 (7)

- October 2024 (5)

- September 2024 (4)

- August 2024 (14)

- July 2024 (13)

- June 2024 (2)

- May 2024 (5)

- April 2024 (13)

- March 2024 (8)

- February 2024 (12)

- January 2024 (14)

- December 2023 (6)

- November 2023 (12)

- October 2023 (24)

- September 2023 (11)

- August 2023 (11)

- July 2023 (9)

- June 2023 (15)

- May 2023 (53)

- April 2023 (5)

- March 2023 (6)

- February 2023 (7)

- January 2023 (3)

- December 2022 (8)

- November 2022 (5)

- October 2022 (11)

- September 2022 (1)

- August 2022 (2)

- July 2022 (1)

- June 2022 (2)

- May 2022 (1)

- March 2022 (1)

- February 2022 (1)

- January 2022 (1)

- December 2021 (3)

- October 2021 (1)

- August 2021 (1)

- June 2021 (1)

- May 2021 (4)

- April 2021 (2)

- March 2021 (4)

- February 2021 (2)

- December 2020 (3)

- November 2020 (1)

- September 2020 (3)

- May 2020 (1)

- April 2020 (2)

- March 2020 (1)

- January 2020 (1)

- December 2019 (1)

- July 2019 (2)

- June 2019 (1)

- April 2019 (2)

- March 2019 (3)

- February 2019 (4)

- December 2018 (1)

- November 2018 (1)

- September 2018 (2)

- August 2018 (1)

- July 2018 (1)

- May 2018 (3)

- April 2018 (1)

- February 2018 (3)

- January 2018 (2)

- December 2017 (3)

- November 2017 (1)

- October 2017 (2)

- September 2017 (4)

- August 2017 (1)

- July 2017 (2)

- June 2017 (2)

- May 2017 (3)

- April 2017 (3)