Share this

Understanding the Kiln Process for Sintering Active Battery Materials

by Therser Sales Team on 31-May-2023 16:05:04

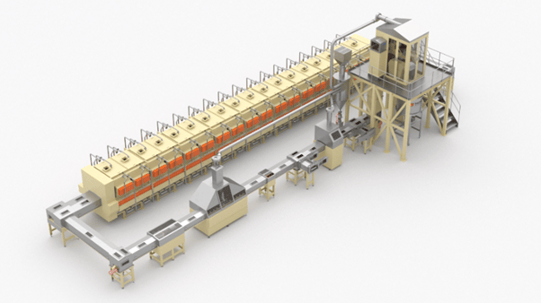

The production of high-performance batteries relies on various manufacturing processes, and one essential step is the kiln process for sintering active battery materials. Sintering involves heating powdered battery materials to enhance their properties and promote particle bonding. In this blog, we will delve into the kiln process for sintering active battery materials, providing insights into its importance and the steps involved.

-

Material Preparation: To begin the kiln process, the active battery material, usually in powdered form, is carefully mixed with binders and additives. This mixture is designed to optimize the material's performance and handling characteristics. Once blended, the material is shaped into desired forms, such as pellets or plates, to facilitate uniform heating during the sintering process.

-

Loading the Kiln: The prepared active battery material is then loaded into the kiln. Attention is given to ensuring proper spacing and distribution to allow for consistent heating and sintering. The arrangement of the material within the kiln is critical to achieve uniform results.

-

Heating and Sintering: As the kiln is heated, the active battery material experiences sintering. The temperature is carefully controlled to be below the melting point of the material but high enough to promote particle bonding. The specific temperature and duration of the sintering process depend on the composition and characteristics of the material being processed.

-

Particle Bonding and Densification: During the sintering process, the powdered particles of the active battery material start bonding together. This bonding occurs through diffusion processes, as atoms migrate across particle boundaries. The result is the densification and strengthening of the material, leading to improved structural integrity and electrical conductivity.

-

Annealing and Cooling: After reaching the desired sintering temperature, the material may undergo an annealing process. Annealing involves holding the material at a lower temperature for a specific duration to relieve stresses and enhance its crystal structure. Subsequently, the material is gradually cooled to room temperature, finalizing the kiln process.

-

Quality Control and Further Processing: Once the material has cooled, it undergoes rigorous quality control checks to ensure proper sintering and desired material properties. These quality control measures are crucial in ensuring the performance and reliability of the active battery material. Depending on the specific application, the sintered material may undergo additional processes, such as coating, calendering, or further assembly steps to complete the battery manufacturing process.

Conclusion: The kiln process for sintering active battery materials plays a vital role in battery manufacturing, enhancing the structural integrity and performance of battery components. By carefully controlling the temperature, duration, and other parameters, the kiln process enables particle bonding and densification. This results in improved electrical conductivity, greater material strength, and enhanced battery efficiency. Understanding the kiln process for sintering active battery materials helps us appreciate the intricate manufacturing steps that contribute to the production of high-performance batteries for various applications.

Please contact our sales team today on 44 (0)1782 824453 or drop us an email to sales@therseruk.com

Share this

- Company News (90)

- Battery Materials (41)

- kiln (37)

- fabrication (29)

- Alloy (27)

- Furnace (27)

- Welding (16)

- Industrial Kilns (15)

- Battery (13)

- Ceramic Kilns (13)

- Processes (13)

- alloy fabrication (13)

- Shuttle Kilns (12)

- RTO’s (11)

- Vacancies (11)

- Hydrogen (10)

- Therser UK (9)

- Tunnel Kiln (9)

- Refractory (8)

- Therser (8)

- Wellman Furnaces (8)

- Brickwork (7)

- Case Studies (7)

- Afterburners (6)

- Fibre Lining (6)

- electric (6)

- Almor Wellman (5)

- thermal engineers (5)

- Biochar (4)

- Exhibition (4)

- Pyrolysis (4)

- Servicing (4)

- Spares (4)

- heat treatment (4)

- History (3)

- Ceramics Uk (2)

- Combustion Control Upgrades (2)

- Nitrogen (2)

- Temperature Control Rings (2)

- gas (2)

- Certificates (1)

- Instrumentation (1)

- MMC (1)

- RHK (1)

- Roller Hearth Kiln (1)

- Test Trials (1)

- aerospace (1)

- analyser (1)

- elec (1)

- oxygen (1)

- vans (1)

- September 2025 (2)

- May 2025 (2)

- March 2025 (1)

- February 2025 (2)

- January 2025 (5)

- December 2024 (5)

- November 2024 (7)

- October 2024 (5)

- September 2024 (4)

- August 2024 (14)

- July 2024 (13)

- June 2024 (2)

- May 2024 (5)

- April 2024 (13)

- March 2024 (8)

- February 2024 (12)

- January 2024 (14)

- December 2023 (6)

- November 2023 (12)

- October 2023 (24)

- September 2023 (11)

- August 2023 (11)

- July 2023 (9)

- June 2023 (15)

- May 2023 (53)

- April 2023 (5)

- March 2023 (6)

- February 2023 (7)

- January 2023 (3)

- December 2022 (8)

- November 2022 (5)

- October 2022 (11)

- September 2022 (1)

- August 2022 (2)

- July 2022 (1)

- June 2022 (2)

- May 2022 (1)

- March 2022 (1)

- February 2022 (1)

- January 2022 (1)

- December 2021 (3)

- October 2021 (1)

- August 2021 (1)

- June 2021 (1)

- May 2021 (4)

- April 2021 (2)

- March 2021 (4)

- February 2021 (2)

- December 2020 (3)

- November 2020 (1)

- September 2020 (3)

- May 2020 (1)

- April 2020 (2)

- March 2020 (1)

- January 2020 (1)

- December 2019 (1)

- July 2019 (2)

- June 2019 (1)

- April 2019 (2)

- March 2019 (3)

- February 2019 (4)

- December 2018 (1)

- November 2018 (1)

- September 2018 (2)

- August 2018 (1)

- July 2018 (1)

- May 2018 (3)

- April 2018 (1)

- February 2018 (3)

- January 2018 (2)

- December 2017 (3)

- November 2017 (1)

- October 2017 (2)

- September 2017 (4)

- August 2017 (1)

- July 2017 (2)

- June 2017 (2)

- May 2017 (3)

- April 2017 (3)