Happy Christmas From Therser!

by Therser Sales Team on 19-Dec-2019 12:12:34

On behalf of our whole team, we would like to wish our customers and suppliers a joyous Christmas and a prosperous 2020.

Join Us At Ceramics UK on 10-11th July 2019!

by Therser UK on 10-Jul-2019 11:56:16

We are very much looking forward to exhibiting at the Ceramics UK exhibition and conference both today and tomorrow! Ceramics UK 2019 is the UK’s premier trade show and conference for the ceramics industry and is actually the only free event of its kind in Europe.

We Are Exhibiting at Ceramics UK 2019 - Stand 1515

by Therser UK on 03-Jul-2019 11:27:22

Therser UK are delighted to announce that we will be exhibiting at Ceramics UK 2019 on the 10th and 11th of July.

Major New Contract For Therser, Staffordshire Kiln Specialist

by Laura James - Business Editor at The Sentinel and Stoke-on-Trent Live on 26-Jun-2019 09:37:05

Pictured: Matthew Pound and Neil Mack of Therser UK Kiln and furnace specialist Therser UK Ltd is gearing up for a double celebration – after landing a major contract with ceramics manufacturer Churchill China in its 10th year in business. Stoke-on-Trent-based Therser UK secured the c …

Therser Behind Stoke’s Push To Become A Ceramics Centre Of Excellence

by Therser Sales Team on 29-Apr-2019 10:00:00

To some, it is known as Stoke-on-Trent. A cosy 36 square miles of industrial history, with a characteristically unassuming name that simply means ‘place on the river’.

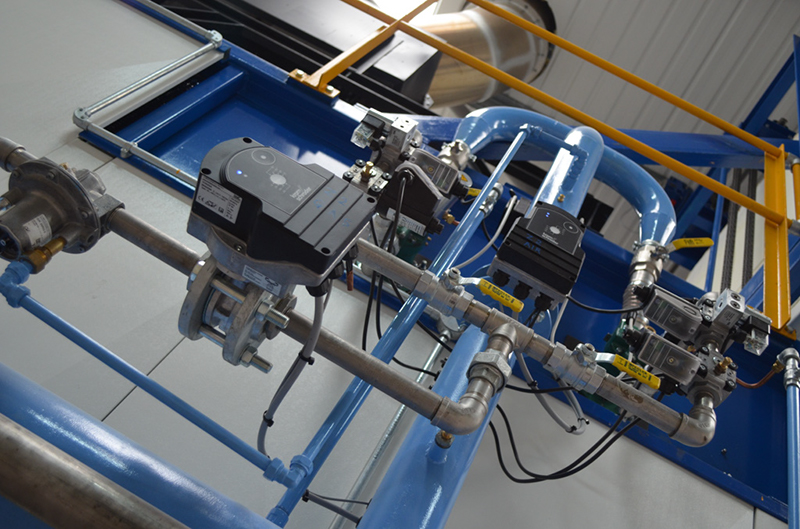

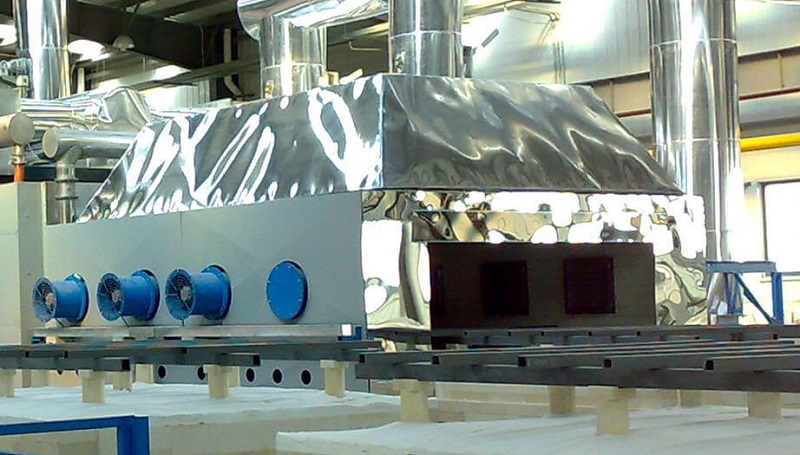

New Pipework Standards Reached & Work Begins

by Therser Sales Team on 26-Apr-2019 09:16:23

There has been significant interest in our latest welding standards accreditation to BS.EN.ISO 9606-1, and at Therser we are now fully into the flow. BS.EN.ISO 9606-1 is a demanding certification that enables us to guarantee the best quality for equally demanding sectors.

Therser Celebrates 10 Years In Business

by Therser Sales Team on 26-Mar-2019 16:21:05

Tuesday 19th March 2019 was a special day for us. Apart from being officially the last day of winter, it was also the day we celebrated 10 years in business. A lot changes in 10 years and it’s good to take stock and think about how far we’ve come and what our team have achieved in thi …

A Warm Welcome To Our New Commissioning Engineer

by Therser Sales Team on 25-Mar-2019 14:02:37

We are delighted to welcome Andrew Wildblood to our team as our latest Commissioning Engineer. Andrew is a highly skilled professional with 40 years’ experience in the industry and is well known in the sector for his skill and expertise! It’s a pleasure to have him on board and we loo …

Therser Are Now The UK's Largest Industrial Kiln Manufacturer!

by Joanne Hunt on 22-Mar-2019 09:46:09

Following a busy year of growth, Therser are now the UK’s largest specialist manufacturer of industrial kilns and furnaces! Changes in the industry and investment in new manufacturing facilities have enabled us to diversify and increase the range of projects we can take on.

How Can Roller Hearth Kilns Help Fight Against Climate Change?

by Therser Sales Team on 11-Feb-2019 11:02:00

Any industrial equipment that uses high levels of energy must be a contributor to carbon dioxide emissions and is, therefore, part of the problem when it comes to climate change – or so conventional wisdom would dictate.