Share this

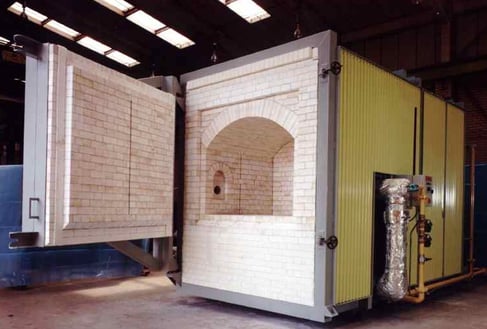

3 Common Mistakes To Avoid When Purchasing An Industrial Kiln/Furnace

by Therser Sales Team on 04-May-2017 09:39:00

Whether you are purchasing your first kiln or have done it before, there are some common errors to be aware of. Learning how to avoid them will ensure the consistent quality of the products you manufacture, as well as saving you much time and money.

1) Changing The Use Of The Equipment From The Original Specification

It is important to get the specification of the kiln/furnace right at the beginning, building in a factor for future expansion and to give you the opportunity to provide sufficient flexibility. A desire to increase the volume of products must be balanced with adjustments to the firing process such as temperature and firing time. Likewise, deciding to change the temperature profile or top temperature without having this built in at the beginning can have disastrous consequences.

The best way to ensure the quality and durability of the products you manufacture is to consider all of the changes that need to be made at each stage of the firing process. Considering this will also ensure that you experience far less downtime and your customers have far fewer delays in delivery.

2) Ensuring The Project Is Under Budget, Rather Than Meeting The Engineering Criteria

There is no doubt that budget is a primary consideration of kiln and furnace purchase. However, it should not be the only consideration. Cutting corners to satisfy the budget can lead to significant reductions in product quality. Worse still are the possible dangers to health and safety that can occur as the result of ignoring engineering criteria.

Safety should be the first consideration when trying to balance budget and engineering requirements. Just as with changing product use, all stages in the process should be considered prior to making any decision with money-saving potential.

3) Insufficient After-Service, Support Or Availability Of Spares

There is no substitute for quality support from your provider, without it costly downtime is the result. In order to ensure consistent quality of your products it is important to always seek out the right kiln or furnace provider. The best company for you will be the one that makes itself available to answer all of your questions from before purchase to long after you’ve started using your kiln or furnace.

Another thing to ensure is that the provider you’ve chosen will be able to supply you with spares in the event that something should go amiss with the products you’ve purchased. They should have the intimate industry knowledge to understand how the failure of a single component can affect your whole manufacturing process, and be ready to assist you in a timely fashion so that production can continue.

The provider you choose should be ready, willing and able to support you, whether you need more information about something, require parts replacement, or need maintenance to be performed on your unit. From kiln and furnace calibration and relining to design and installation, having the knowledge and expertise of a provider on your side will offer several benefits that will last well beyond the initial sale.

Share this

- Company News (90)

- Battery Materials (41)

- kiln (37)

- fabrication (29)

- Alloy (27)

- Furnace (27)

- Welding (16)

- Industrial Kilns (15)

- Battery (13)

- Ceramic Kilns (13)

- Processes (13)

- alloy fabrication (13)

- Shuttle Kilns (12)

- RTO’s (11)

- Vacancies (11)

- Hydrogen (10)

- Therser UK (9)

- Tunnel Kiln (9)

- Refractory (8)

- Therser (8)

- Wellman Furnaces (8)

- Brickwork (7)

- Case Studies (7)

- Afterburners (6)

- Fibre Lining (6)

- electric (6)

- Almor Wellman (5)

- thermal engineers (5)

- Biochar (4)

- Exhibition (4)

- Pyrolysis (4)

- Servicing (4)

- Spares (4)

- heat treatment (4)

- History (3)

- Ceramics Uk (2)

- Combustion Control Upgrades (2)

- Nitrogen (2)

- Temperature Control Rings (2)

- gas (2)

- Certificates (1)

- Instrumentation (1)

- MMC (1)

- RHK (1)

- Roller Hearth Kiln (1)

- Test Trials (1)

- aerospace (1)

- analyser (1)

- elec (1)

- oxygen (1)

- vans (1)

- September 2025 (2)

- May 2025 (2)

- March 2025 (1)

- February 2025 (2)

- January 2025 (5)

- December 2024 (5)

- November 2024 (7)

- October 2024 (5)

- September 2024 (4)

- August 2024 (14)

- July 2024 (13)

- June 2024 (2)

- May 2024 (5)

- April 2024 (13)

- March 2024 (8)

- February 2024 (12)

- January 2024 (14)

- December 2023 (6)

- November 2023 (12)

- October 2023 (24)

- September 2023 (11)

- August 2023 (11)

- July 2023 (9)

- June 2023 (15)

- May 2023 (53)

- April 2023 (5)

- March 2023 (6)

- February 2023 (7)

- January 2023 (3)

- December 2022 (8)

- November 2022 (5)

- October 2022 (11)

- September 2022 (1)

- August 2022 (2)

- July 2022 (1)

- June 2022 (2)

- May 2022 (1)

- March 2022 (1)

- February 2022 (1)

- January 2022 (1)

- December 2021 (3)

- October 2021 (1)

- August 2021 (1)

- June 2021 (1)

- May 2021 (4)

- April 2021 (2)

- March 2021 (4)

- February 2021 (2)

- December 2020 (3)

- November 2020 (1)

- September 2020 (3)

- May 2020 (1)

- April 2020 (2)

- March 2020 (1)

- January 2020 (1)

- December 2019 (1)

- July 2019 (2)

- June 2019 (1)

- April 2019 (2)

- March 2019 (3)

- February 2019 (4)

- December 2018 (1)

- November 2018 (1)

- September 2018 (2)

- August 2018 (1)

- July 2018 (1)

- May 2018 (3)

- April 2018 (1)

- February 2018 (3)

- January 2018 (2)

- December 2017 (3)

- November 2017 (1)

- October 2017 (2)

- September 2017 (4)

- August 2017 (1)

- July 2017 (2)

- June 2017 (2)

- May 2017 (3)

- April 2017 (3)