Share this

Unleashing Precision: Temperature Control in Kilns

by Therser UK on 29-Jun-2023 16:22:16

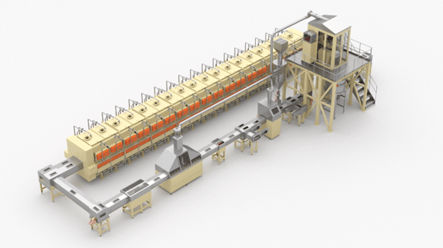

Welcome back to our blog series focused on Therser UK's expertise in kiln manufacturing for the battery powder sintering market. In this post, we will delve into the importance of precise temperature control during the sintering process and highlight the advanced technologies employed by Therser UK to ensure accurate and consistent heat distribution.

-

The Significance of Temperature Control in Sintering: Temperature control is crucial in battery powder sintering, as it directly affects the quality and properties of the sintered battery materials. Consistent and accurate temperature profiles throughout the kiln ensure uniform sintering and minimize the risk of defects. Therser UK understands the critical role of temperature control and has developed innovative solutions to address this challenge.

-

Therser UK's Advanced Temperature Control Technologies: Therser UK employs advanced temperature control technologies to achieve precise and reliable temperature profiles in kilns for battery powder sintering. Our kilns are equipped with highly sensitive temperature sensors that continuously monitor the thermal conditions inside the kiln. This data is fed into our sophisticated control systems, which make real-time adjustments to maintain the desired temperature setpoints.

-

Uniform Temperature Distribution: Achieving uniform temperature distribution across the entire sintering chamber is essential for consistent sintering outcomes. Therser UK employs carefully engineered airflow management systems and strategically placed heating elements to ensure even heat distribution throughout the kiln. This eliminates temperature variations and guarantees that every battery component undergoes the sintering process under optimal conditions.

-

Precision Control for Enhanced Quality: Therser UK's advanced control systems provide manufacturers with precise control over temperature profiles during battery powder sintering. Our systems allow for fine-tuning of temperature gradients, ramp rates, and dwell times to meet the specific requirements of different battery materials and components. This level of control contributes to improved product quality, enhanced material properties, and reduced waste.

Conclusion: Therser UK recognizes the paramount importance of precise temperature control in kilns for battery powder sintering. By utilizing advanced temperature control technologies, ensuring uniform temperature distribution, and providing precision control over temperature profiles, Therser UK empowers manufacturers in the battery industry to achieve superior sintering outcomes. Our commitment to accuracy and consistency sets us apart in the market, enabling our customers to produce high-quality battery materials with enhanced performance.

In the next blog post, we will explore the energy efficiency aspects of Therser UK's kiln designs. Stay tuned to discover how our innovative approaches to heat recovery, insulation techniques, and optimized airflow management contribute to significant energy savings and environmental sustainability in the battery powder sintering process.

Contact Us: For quotes, questions, and sales inquiries, please reach out to our dedicated technical sales team:

- Phone: +44 (0) 1782 824 453

- Email: sales@therseruk.com

- Social Media: Find us on Facebook Twitter

- https://www.therseruk.com/

Share this

- Company News (90)

- Battery Materials (41)

- kiln (37)

- fabrication (29)

- Alloy (27)

- Furnace (27)

- Welding (16)

- Industrial Kilns (15)

- Battery (13)

- Ceramic Kilns (13)

- Processes (13)

- alloy fabrication (13)

- Shuttle Kilns (12)

- RTO’s (11)

- Vacancies (11)

- Hydrogen (10)

- Therser UK (9)

- Tunnel Kiln (9)

- Refractory (8)

- Therser (8)

- Wellman Furnaces (8)

- Brickwork (7)

- Case Studies (7)

- Afterburners (6)

- Fibre Lining (6)

- electric (6)

- Almor Wellman (5)

- thermal engineers (5)

- Biochar (4)

- Exhibition (4)

- Pyrolysis (4)

- Servicing (4)

- Spares (4)

- heat treatment (4)

- History (3)

- Ceramics Uk (2)

- Combustion Control Upgrades (2)

- Nitrogen (2)

- Temperature Control Rings (2)

- gas (2)

- Certificates (1)

- Instrumentation (1)

- MMC (1)

- RHK (1)

- Roller Hearth Kiln (1)

- Test Trials (1)

- aerospace (1)

- analyser (1)

- elec (1)

- oxygen (1)

- vans (1)

- September 2025 (2)

- May 2025 (2)

- March 2025 (1)

- February 2025 (2)

- January 2025 (5)

- December 2024 (5)

- November 2024 (7)

- October 2024 (5)

- September 2024 (4)

- August 2024 (14)

- July 2024 (13)

- June 2024 (2)

- May 2024 (5)

- April 2024 (13)

- March 2024 (8)

- February 2024 (12)

- January 2024 (14)

- December 2023 (6)

- November 2023 (12)

- October 2023 (24)

- September 2023 (11)

- August 2023 (11)

- July 2023 (9)

- June 2023 (15)

- May 2023 (53)

- April 2023 (5)

- March 2023 (6)

- February 2023 (7)

- January 2023 (3)

- December 2022 (8)

- November 2022 (5)

- October 2022 (11)

- September 2022 (1)

- August 2022 (2)

- July 2022 (1)

- June 2022 (2)

- May 2022 (1)

- March 2022 (1)

- February 2022 (1)

- January 2022 (1)

- December 2021 (3)

- October 2021 (1)

- August 2021 (1)

- June 2021 (1)

- May 2021 (4)

- April 2021 (2)

- March 2021 (4)

- February 2021 (2)

- December 2020 (3)

- November 2020 (1)

- September 2020 (3)

- May 2020 (1)

- April 2020 (2)

- March 2020 (1)

- January 2020 (1)

- December 2019 (1)

- July 2019 (2)

- June 2019 (1)

- April 2019 (2)

- March 2019 (3)

- February 2019 (4)

- December 2018 (1)

- November 2018 (1)

- September 2018 (2)

- August 2018 (1)

- July 2018 (1)

- May 2018 (3)

- April 2018 (1)

- February 2018 (3)

- January 2018 (2)

- December 2017 (3)

- November 2017 (1)

- October 2017 (2)

- September 2017 (4)

- August 2017 (1)

- July 2017 (2)

- June 2017 (2)

- May 2017 (3)

- April 2017 (3)