Share this

Therser Wellman Fabrications: Enhancing Industrial Furnace Performance with Essential Components

by Therser UK on 10-Oct-2023 10:51:57

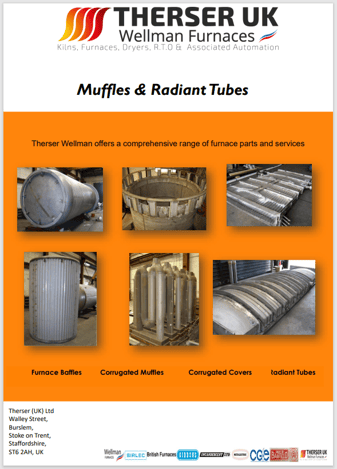

Furnaces play a crucial role in various industrial processes, from heat treatment to metal casting and beyond. Within these high-temperature environments, several components are employed to optimize efficiency, temperature uniformity, and overall performance. In this blog, we will look into four essential furnace components: Furnace Baffles, Corrugated Muffles, Corrugated Covers, and Radiant Tubes, exploring their functions and significance in industrial heating processes.

Furnace BafflesFurnace baffles are vital components designed to enhance heat distribution and temperature uniformity within a furnace chamber. These devices consist of heat-resistant materials such as refractory metals, ceramics, or alloys, and they are strategically placed within the furnace to control the flow of heat and gases. The primary functions of furnace baffles are:

a. Temperature Regulation: Furnace baffles help regulate temperature gradients within the furnace by directing the flow of hot gases and ensuring that heat is evenly distributed to all parts of the chamber.

b. Preventing Direct Heat Exposure: They shield sensitive components or materials from direct exposure to high-temperature flames or combustion gases, reducing the risk of overheating or damage.

c. Enhancing Efficiency: By optimizing heat transfer and minimizing heat loss, baffles contribute to energy efficiency in industrial processes.

Corrugated MufflesCorrugated muffles are specialized components used in controlled atmosphere and vacuum furnaces. They are typically constructed from heat-resistant materials, like ceramics or refractory metals, and feature a corrugated design, resembling a series of ridges or waves. These ridges create a tortuous path for gases and heat to follow, resulting in several key benefits:

a. Enhanced Uniformity: Corrugated muffles promote even temperature distribution and prevent hotspots by disrupting the flow of gases and heat within the furnace chamber.

b. Improved Heat Transfer: The increased surface area provided by the corrugated design improves heat transfer efficiency, allowing for faster and more uniform heating and cooling of materials.

c. Reduced Contamination: In controlled atmosphere furnaces, corrugated muffles can help maintain the purity of the processing environment by minimizing contact between the workpiece and potentially contaminating gases.

Corrugated Covers

Corrugated covers, similar to corrugated muffles, feature a ridged or wavy design and are used to enclose the top portion of the furnace chamber. These covers serve multiple functions in high-temperature industrial processes:

a. Heat Reflection: The corrugations in the cover help reflect radiant heat back into the furnace, increasing the overall thermal efficiency of the system.

b. Containment: Corrugated covers help contain heat and gases within the furnace chamber, reducing heat loss and maintaining a controlled processing environment.

c. Improved Atmosphere Control: In processes requiring precise control of the atmosphere, corrugated covers can help maintain the desired gas composition and prevent unwanted infiltration.

Radiant TubesRadiant tubes are a crucial component in many high-temperature furnaces and are used for indirect heating of materials. These tubes are typically made from heat-resistant materials like ceramic or metal alloys and are positioned within the furnace chamber. Radiant tubes operate based on the principle of radiant heat transfer, where the heat is emitted from the tube's surface and radiated onto the workpiece. Key advantages of using radiant tubes include:

a. Precise Temperature Control: Radiant tubes offer precise temperature control and uniform heating, making them ideal for applications requiring consistent and predictable heat treatment.

b. Reduced Oxidation: In controlled atmospheres, radiant tubes can help minimize oxidation of materials by preventing direct contact with combustion gases.

c. Energy Efficiency: Radiant tubes are known for their energy efficiency, as they maximize heat transfer to the workpiece while minimizing heat loss.

Furnace baffles, corrugated muffles, corrugated covers, and radiant tubes are essential components in various industrial heating processes. They contribute to temperature uniformity, heat distribution, and overall furnace efficiency. As technology continues to advance, these components will likely undergo further refinements, leading to even more precise and efficient industrial heating solutions. Understanding the role of these components is crucial for optimizing the performance of industrial furnaces and ensuring the quality of materials and products produced within them.

Please contact our sales team today on 44 (0)1782 824453 or drop us an email

Topics: alloy fabrication

Share this

- Company News (90)

- Battery Materials (41)

- kiln (37)

- fabrication (29)

- Alloy (27)

- Furnace (27)

- Welding (16)

- Industrial Kilns (15)

- Battery (13)

- Ceramic Kilns (13)

- Processes (13)

- alloy fabrication (13)

- Shuttle Kilns (12)

- RTO’s (11)

- Vacancies (11)

- Hydrogen (10)

- Therser UK (9)

- Tunnel Kiln (9)

- Refractory (8)

- Therser (8)

- Wellman Furnaces (8)

- Brickwork (7)

- Case Studies (7)

- Afterburners (6)

- Fibre Lining (6)

- electric (6)

- Almor Wellman (5)

- thermal engineers (5)

- Biochar (4)

- Exhibition (4)

- Pyrolysis (4)

- Servicing (4)

- Spares (4)

- heat treatment (4)

- History (3)

- Ceramics Uk (2)

- Combustion Control Upgrades (2)

- Nitrogen (2)

- Temperature Control Rings (2)

- gas (2)

- Certificates (1)

- Instrumentation (1)

- MMC (1)

- RHK (1)

- Roller Hearth Kiln (1)

- Test Trials (1)

- aerospace (1)

- analyser (1)

- elec (1)

- oxygen (1)

- vans (1)

- September 2025 (2)

- May 2025 (2)

- March 2025 (1)

- February 2025 (2)

- January 2025 (5)

- December 2024 (5)

- November 2024 (7)

- October 2024 (5)

- September 2024 (4)

- August 2024 (14)

- July 2024 (13)

- June 2024 (2)

- May 2024 (5)

- April 2024 (13)

- March 2024 (8)

- February 2024 (12)

- January 2024 (14)

- December 2023 (6)

- November 2023 (12)

- October 2023 (24)

- September 2023 (11)

- August 2023 (11)

- July 2023 (9)

- June 2023 (15)

- May 2023 (53)

- April 2023 (5)

- March 2023 (6)

- February 2023 (7)

- January 2023 (3)

- December 2022 (8)

- November 2022 (5)

- October 2022 (11)

- September 2022 (1)

- August 2022 (2)

- July 2022 (1)

- June 2022 (2)

- May 2022 (1)

- March 2022 (1)

- February 2022 (1)

- January 2022 (1)

- December 2021 (3)

- October 2021 (1)

- August 2021 (1)

- June 2021 (1)

- May 2021 (4)

- April 2021 (2)

- March 2021 (4)

- February 2021 (2)

- December 2020 (3)

- November 2020 (1)

- September 2020 (3)

- May 2020 (1)

- April 2020 (2)

- March 2020 (1)

- January 2020 (1)

- December 2019 (1)

- July 2019 (2)

- June 2019 (1)

- April 2019 (2)

- March 2019 (3)

- February 2019 (4)

- December 2018 (1)

- November 2018 (1)

- September 2018 (2)

- August 2018 (1)

- July 2018 (1)

- May 2018 (3)

- April 2018 (1)

- February 2018 (3)

- January 2018 (2)

- December 2017 (3)

- November 2017 (1)

- October 2017 (2)

- September 2017 (4)

- August 2017 (1)

- July 2017 (2)

- June 2017 (2)

- May 2017 (3)

- April 2017 (3)