Share this

THERSER UK's Electrically Fired Test Kiln is Ready for Your Product!

by Therser UK on 08-Jan-2024 08:36:59

THERSER UK's versatile medium-sized eclectically fired test kiln is a game-changer in the industry, offering a capacity that can accommodate up to 8 saggars of material. This means that you can fire a substantial amount of products in one go, saving you time and energy. However, what sets this kiln apart is its ability to be used for testing purposes without the need for saggars (product dependent). This flexibility allows you to experiment with different materials and processes, giving you the freedom to push the boundaries of your product.

With a working internal chamber width of 900mm, height of 300mm, and length of 900mm, this kiln provides ample space for your product.. And with a top temperature of 1250c, you can achieve the perfect firing conditions for a wide range of materials.

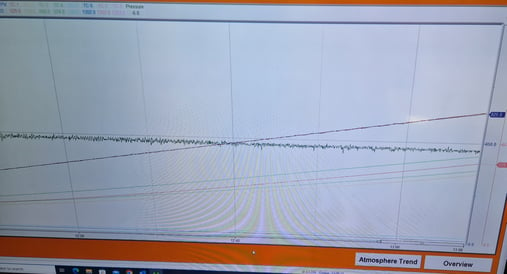

When it comes to firing cycles, the choice is yours. Whether you prefer a slow and controlled firing or a rapid firings, this kiln can accommodate your needs. And with an atmosphere control chamber maintaining a level of less than 50ppm, you can rest assured that your products will be fired in the optimal environment.

So, what can you fire in this exceptional kiln? The possibilities are endless. From battery powders and powder chemicals to ceramics and carbon fibers, this kiln can handle it all. Even heavy clay and aerospace materials are no match for its capabilities. And if you're working with organic materials or powder metals, this kiln is your perfect partner.

But it's not just the size and temperature that make this kiln exceptional. Therser has also equipped it with two internal thermocouples, ensuring accurate temperature monitoring throughout the firing process. Additionally, the kiln allows for the placement of any 32 thermocouple products, giving you the flexibility to monitor specific areas or materials.

Specification

Up to 8 saggars or equivalent product

Working Internal chamber Width 900mm

Working Internal chamber Height 300mm

Working Internal chamber Length 900mm

Top temperature 1250c

Process gases of your choice

2 Internal Thermocouples

Any 32 Thermocouple product placement

Firing cycle of your choice

Most products can be fired

Atmosphere control chamber – Less than 50ppm

Scada/Specview data

Mass flow control

O2 analyser

Energy consumption report

Therser also understands the importance of sustainability in kiln operations. That's why they have included an afterburner in their design. This specialized device eliminates volatile organic compounds (VOCs) emitted during the firing process, ensuring that harmful pollutants are broken down into less harmful substances like carbon dioxide and water. By using this kiln, you are not only creating beautiful creations but also contributing to a cleaner and greener environment.

What can we fire?

•Battery powders

•Powder chemicals

•Ceramics

•Carbon fibers

•Heavy clay

•Aerospace

•Organic materials

•Powder metals

In conclusion, Therser's versatile medium-sized test kiln offers a world of possibilities for your firing needs. Its capacity, temperature range, and advanced features make it a must-have for testing your product in an eclectically fired environment.

For all enquires please call 01782 824453

Email sales@therseruk.com

Share this

- Company News (90)

- Battery Materials (41)

- kiln (37)

- fabrication (29)

- Alloy (27)

- Furnace (27)

- Welding (16)

- Industrial Kilns (15)

- Battery (13)

- Ceramic Kilns (13)

- Processes (13)

- alloy fabrication (13)

- Shuttle Kilns (12)

- RTO’s (11)

- Vacancies (11)

- Hydrogen (10)

- Therser UK (9)

- Tunnel Kiln (9)

- Refractory (8)

- Therser (8)

- Wellman Furnaces (8)

- Brickwork (7)

- Case Studies (7)

- Afterburners (6)

- Fibre Lining (6)

- electric (6)

- Almor Wellman (5)

- thermal engineers (5)

- Biochar (4)

- Exhibition (4)

- Pyrolysis (4)

- Servicing (4)

- Spares (4)

- heat treatment (4)

- History (3)

- Ceramics Uk (2)

- Combustion Control Upgrades (2)

- Nitrogen (2)

- Temperature Control Rings (2)

- gas (2)

- Certificates (1)

- Instrumentation (1)

- MMC (1)

- RHK (1)

- Roller Hearth Kiln (1)

- Test Trials (1)

- aerospace (1)

- analyser (1)

- elec (1)

- oxygen (1)

- vans (1)

- September 2025 (2)

- May 2025 (2)

- March 2025 (1)

- February 2025 (2)

- January 2025 (5)

- December 2024 (5)

- November 2024 (7)

- October 2024 (5)

- September 2024 (4)

- August 2024 (14)

- July 2024 (13)

- June 2024 (2)

- May 2024 (5)

- April 2024 (13)

- March 2024 (8)

- February 2024 (12)

- January 2024 (14)

- December 2023 (6)

- November 2023 (12)

- October 2023 (24)

- September 2023 (11)

- August 2023 (11)

- July 2023 (9)

- June 2023 (15)

- May 2023 (53)

- April 2023 (5)

- March 2023 (6)

- February 2023 (7)

- January 2023 (3)

- December 2022 (8)

- November 2022 (5)

- October 2022 (11)

- September 2022 (1)

- August 2022 (2)

- July 2022 (1)

- June 2022 (2)

- May 2022 (1)

- March 2022 (1)

- February 2022 (1)

- January 2022 (1)

- December 2021 (3)

- October 2021 (1)

- August 2021 (1)

- June 2021 (1)

- May 2021 (4)

- April 2021 (2)

- March 2021 (4)

- February 2021 (2)

- December 2020 (3)

- November 2020 (1)

- September 2020 (3)

- May 2020 (1)

- April 2020 (2)

- March 2020 (1)

- January 2020 (1)

- December 2019 (1)

- July 2019 (2)

- June 2019 (1)

- April 2019 (2)

- March 2019 (3)

- February 2019 (4)

- December 2018 (1)

- November 2018 (1)

- September 2018 (2)

- August 2018 (1)

- July 2018 (1)

- May 2018 (3)

- April 2018 (1)

- February 2018 (3)

- January 2018 (2)

- December 2017 (3)

- November 2017 (1)

- October 2017 (2)

- September 2017 (4)

- August 2017 (1)

- July 2017 (2)

- June 2017 (2)

- May 2017 (3)

- April 2017 (3)