Share this

How Does Therser UK Analyse Oxygen Levels in our Kilns in Realtime?

by Therser UK on 26-Jul-2023 10:57:30

Taking oxygen out of a kiln is important for several reasons:

- Controlling the Temperature: Oxygen is required for combustion to occur, so by reducing the amount of oxygen in the kiln, the temperature can be more precisely controlled. By adjusting the amount of oxygen, the temperature inside the kiln can be increased or decreased as needed. This is important for ensuring that the materials being processed are heated or cooled at the appropriate rate.

- Preventing Oxidation: Oxygen can cause oxidation in some materials, which can result in unwanted chemical reactions or changes to the material being processed. By reducing the amount of oxygen in the kiln, these unwanted reactions can be prevented, ensuring that the materials are not damaged or altered in undesirable ways.

- Reducing Fuel Consumption: By reducing the amount of oxygen in the kiln, the amount of fuel required to maintain a particular temperature can be reduced. This is because oxygen is required for combustion, so by reducing the amount of oxygen, the combustion process is less efficient, requiring less fuel to maintain the same temperature.

- Minimising Emissions: Oxygen is required for complete combustion to occur, which produces carbon dioxide and other emissions. By reducing the amount of oxygen in the kiln, the amount of emissions can be minimized, reducing the environmental impact of the kiln. This is particularly important in industries that produce a lot of emissions, such as ceramics or cement manufacturing.

Overall, taking oxygen out of a kiln is an important step in many industrial processes to ensure that materials are processed efficiently and effectively, while minimizing negative impacts on the environment.

Nitrogen is often used to clear a kiln of oxygen for several reasons:

-

Inert Gas: Nitrogen is an inert gas, which means that it does not react with other materials. This makes it an ideal gas to use for displacing oxygen, as it will not react with the materials being processed or change their properties.

-

Non-Toxic and Inexpensive: Nitrogen is a non-toxic gas that is widely available and relatively inexpensive. This makes it an attractive option for use in industrial processes, as it is a safe and cost-effective gas to use.

-

High Purity: Nitrogen is typically available in high purity grades, which means that it is free from impurities that could contaminate the materials being processed. This is important in industries such as electronics or pharmaceuticals, where even trace amounts of impurities can have a significant impact on the final product.

-

Easy to Control: Nitrogen is easy to control, as it can be introduced into the kiln in a controlled manner, either through a valve or other mechanism. This allows for precise control over the amount of oxygen in the kiln and can help to ensure that the temperature is maintained at the appropriate level.

By using nitrogen to clear a kiln of oxygen, the risk of unwanted chemical reactions or changes to the materials being processed is minimized, while the temperature can be precisely controlled. This is particularly important in industries where the quality and consistency of the final product are critical, such as in the manufacture of electronic components or pharmaceuticals.

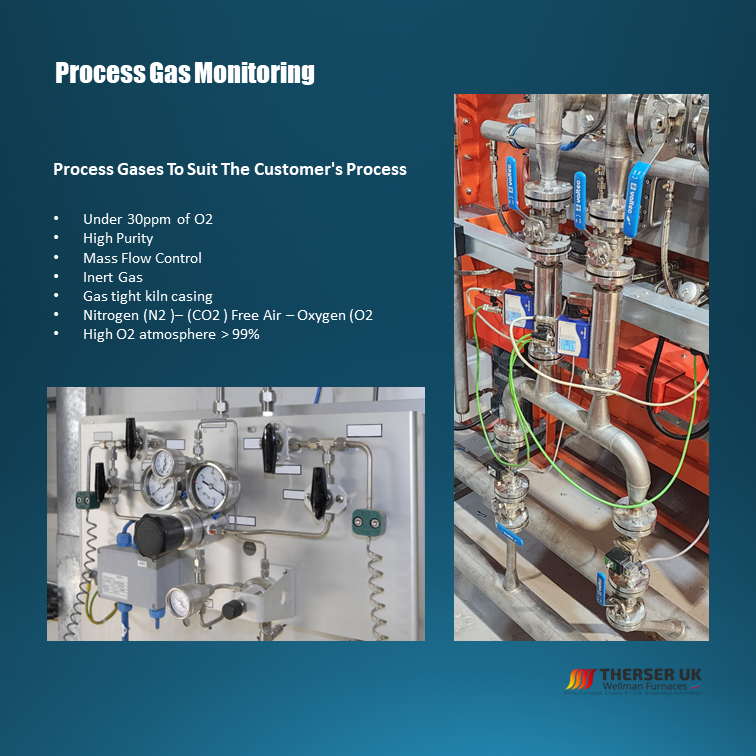

So how do we regulate Oxygen and Nitrogen levels?

How do we make sure that our clients aren't using more then they need to?

Both these questions make what we do at Therser UK invaluable, our test kilns at the heart of our innovation.

Therser UK is investing heavily into this technology. Controlling Oxygen levels will in turn reduce running costs for product manufacture. Also ensuring no contamination occurs in their firing cycle.

The oxygen analyser works by measuring the partial pressure of oxygen in the exhaust gas stream. It typically consists of a sensing element, which is usually made from zirconium oxide, and an electronic control unit (PLC). The sensing element is heated to a high temperature and exposed to the exhaust gas stream. As oxygen in the gas stream comes into contact with the sensing element, it reacts with the zirconium oxide, creating a voltage signal that is proportional to the oxygen concentration.

The PLC processes this voltage signal and converts it into a numerical value, which can be displayed on a monitor or used to control the combustion process in the kiln. By monitoring the oxygen concentration in the exhaust gas, the oxygen analyser can provide real-time feedback on the combustion process and enable operators to adjust the amount of fuel and air being supplied to the kiln to maintain optimal operating conditions.

The use of an oxygen analyser is important in industrial processes because it can help to improve efficiency, reduce emissions, and ensure that the final product meets quality standards. By providing accurate and reliable feedback on the combustion process, the oxygen analyser can help to optimize the use of fuel and reduce energy costs, while also minimizing emissions of pollutants such as nitrogen oxides and carbon monoxide.

It doesn't matter if your project is small or on a huge scale we can help. Our engineers can also retrofit existing kilns with new fibre linings to improve their efficiency and productivity. To discuss your requirements please call 01782 824453, or email sales@therseruk.com

Share this

- Company News (90)

- Battery Materials (41)

- kiln (37)

- fabrication (29)

- Alloy (27)

- Furnace (27)

- Welding (16)

- Industrial Kilns (15)

- Battery (13)

- Ceramic Kilns (13)

- Processes (13)

- alloy fabrication (13)

- Shuttle Kilns (12)

- RTO’s (11)

- Vacancies (11)

- Hydrogen (10)

- Therser UK (9)

- Tunnel Kiln (9)

- Refractory (8)

- Therser (8)

- Wellman Furnaces (8)

- Brickwork (7)

- Case Studies (7)

- Afterburners (6)

- Fibre Lining (6)

- electric (6)

- Almor Wellman (5)

- thermal engineers (5)

- Biochar (4)

- Exhibition (4)

- Pyrolysis (4)

- Servicing (4)

- Spares (4)

- heat treatment (4)

- History (3)

- Ceramics Uk (2)

- Combustion Control Upgrades (2)

- Nitrogen (2)

- Temperature Control Rings (2)

- gas (2)

- Certificates (1)

- Instrumentation (1)

- MMC (1)

- RHK (1)

- Roller Hearth Kiln (1)

- Test Trials (1)

- aerospace (1)

- analyser (1)

- elec (1)

- oxygen (1)

- vans (1)

- September 2025 (2)

- May 2025 (2)

- March 2025 (1)

- February 2025 (2)

- January 2025 (5)

- December 2024 (5)

- November 2024 (7)

- October 2024 (5)

- September 2024 (4)

- August 2024 (14)

- July 2024 (13)

- June 2024 (2)

- May 2024 (5)

- April 2024 (13)

- March 2024 (8)

- February 2024 (12)

- January 2024 (14)

- December 2023 (6)

- November 2023 (12)

- October 2023 (24)

- September 2023 (11)

- August 2023 (11)

- July 2023 (9)

- June 2023 (15)

- May 2023 (53)

- April 2023 (5)

- March 2023 (6)

- February 2023 (7)

- January 2023 (3)

- December 2022 (8)

- November 2022 (5)

- October 2022 (11)

- September 2022 (1)

- August 2022 (2)

- July 2022 (1)

- June 2022 (2)

- May 2022 (1)

- March 2022 (1)

- February 2022 (1)

- January 2022 (1)

- December 2021 (3)

- October 2021 (1)

- August 2021 (1)

- June 2021 (1)

- May 2021 (4)

- April 2021 (2)

- March 2021 (4)

- February 2021 (2)

- December 2020 (3)

- November 2020 (1)

- September 2020 (3)

- May 2020 (1)

- April 2020 (2)

- March 2020 (1)

- January 2020 (1)

- December 2019 (1)

- July 2019 (2)

- June 2019 (1)

- April 2019 (2)

- March 2019 (3)

- February 2019 (4)

- December 2018 (1)

- November 2018 (1)

- September 2018 (2)

- August 2018 (1)

- July 2018 (1)

- May 2018 (3)

- April 2018 (1)

- February 2018 (3)

- January 2018 (2)

- December 2017 (3)

- November 2017 (1)

- October 2017 (2)

- September 2017 (4)

- August 2017 (1)

- July 2017 (2)

- June 2017 (2)

- May 2017 (3)

- April 2017 (3)