Share this

Energy Efficiency: Reducing Costs and Environmental Impact

by Therser UK on 29-Jun-2023 10:59:54

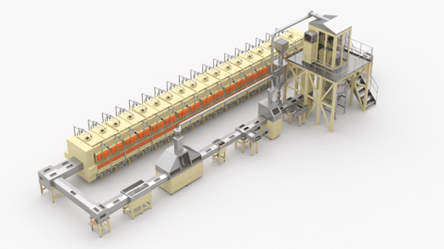

Welcome back to our blog series on Therser UK's expertise in kiln manufacturing for the battery powder sintering market. In this post, we will focus on the importance of energy efficiency in kiln design and how Therser UK's innovative solutions help reduce costs and minimize environmental impact.

-

The Need for Energy Efficiency: Energy consumption is a significant factor in manufacturing processes, and kilns used in battery powder sintering are no exception. High energy demands not only contribute to increased operating costs but also have environmental implications. Therser UK recognizes the importance of energy efficiency and has developed strategies to address this challenge.

-

Heat Recovery Systems: Therser UK incorporates heat recovery systems into its kiln designs to maximize energy efficiency. These systems capture and utilize waste heat generated during the sintering process, effectively recycling it for preheating combustion air or other heating requirements. By utilizing waste heat, Therser UK kilns significantly reduce energy consumption and enhance overall thermal efficiency.

-

Optimal Insulation Techniques: Insulation is a key component of energy-efficient kiln design. Therser UK utilizes advanced insulation materials with superior thermal properties to minimize heat loss and ensure maximum heat retention within the kiln. By reducing thermal losses, our kilns require less energy input to maintain desired temperature levels, resulting in substantial energy savings.

-

Optimized Airflow Management: Efficient airflow management is crucial for energy-efficient kiln operation. Therser UK implements optimized airflow systems that facilitate better heat transfer and distribution throughout the kiln. By strategically controlling the flow of combustion air and exhaust gases, we minimize energy wastage and improve the overall thermal efficiency of the kiln.

-

Environmental Sustainability: Therser UK's commitment to energy efficiency extends to environmental sustainability. By reducing energy consumption, our kilns contribute to a lower carbon footprint, reduced greenhouse gas emissions, and a more sustainable manufacturing process. With our energy-efficient kilns, manufacturers can align their operations with green initiatives and environmental regulations.

Conclusion: Therser UK's dedication to energy efficiency in kiln design for battery powder sintering brings tangible benefits to manufacturers, including reduced operating costs and minimized environmental impact. By incorporating heat recovery systems, optimal insulation techniques, and optimized airflow management, Therser UK kilns offer exceptional energy efficiency without compromising sintering quality.

In the next blog post, we will showcase success stories from Therser UK's satisfied customers in the battery industry. Stay tuned to learn how our kilns have transformed production efficiency, improved product quality, and accelerated the development of next-generation batteries.

Contact Us: For quotes, questions, and sales inquiries, please reach out to our dedicated technical sales team:

- Phone: +44 (0) 1782 824 453

- Email: sales@therseruk.com

- Social Media: Find us on Facebook Twitter

- https://www.therseruk.com/

Share this

- Company News (90)

- Battery Materials (41)

- kiln (37)

- fabrication (29)

- Alloy (27)

- Furnace (27)

- Welding (16)

- Industrial Kilns (15)

- Battery (13)

- Ceramic Kilns (13)

- Processes (13)

- alloy fabrication (13)

- Shuttle Kilns (12)

- RTO’s (11)

- Vacancies (11)

- Hydrogen (10)

- Therser UK (9)

- Tunnel Kiln (9)

- Refractory (8)

- Therser (8)

- Wellman Furnaces (8)

- Brickwork (7)

- Case Studies (7)

- Afterburners (6)

- Fibre Lining (6)

- electric (6)

- Almor Wellman (5)

- thermal engineers (5)

- Biochar (4)

- Exhibition (4)

- Pyrolysis (4)

- Servicing (4)

- Spares (4)

- heat treatment (4)

- History (3)

- Ceramics Uk (2)

- Combustion Control Upgrades (2)

- Nitrogen (2)

- Temperature Control Rings (2)

- gas (2)

- Certificates (1)

- Instrumentation (1)

- MMC (1)

- RHK (1)

- Roller Hearth Kiln (1)

- Test Trials (1)

- aerospace (1)

- analyser (1)

- elec (1)

- oxygen (1)

- vans (1)

- September 2025 (2)

- May 2025 (2)

- March 2025 (1)

- February 2025 (2)

- January 2025 (5)

- December 2024 (5)

- November 2024 (7)

- October 2024 (5)

- September 2024 (4)

- August 2024 (14)

- July 2024 (13)

- June 2024 (2)

- May 2024 (5)

- April 2024 (13)

- March 2024 (8)

- February 2024 (12)

- January 2024 (14)

- December 2023 (6)

- November 2023 (12)

- October 2023 (24)

- September 2023 (11)

- August 2023 (11)

- July 2023 (9)

- June 2023 (15)

- May 2023 (53)

- April 2023 (5)

- March 2023 (6)

- February 2023 (7)

- January 2023 (3)

- December 2022 (8)

- November 2022 (5)

- October 2022 (11)

- September 2022 (1)

- August 2022 (2)

- July 2022 (1)

- June 2022 (2)

- May 2022 (1)

- March 2022 (1)

- February 2022 (1)

- January 2022 (1)

- December 2021 (3)

- October 2021 (1)

- August 2021 (1)

- June 2021 (1)

- May 2021 (4)

- April 2021 (2)

- March 2021 (4)

- February 2021 (2)

- December 2020 (3)

- November 2020 (1)

- September 2020 (3)

- May 2020 (1)

- April 2020 (2)

- March 2020 (1)

- January 2020 (1)

- December 2019 (1)

- July 2019 (2)

- June 2019 (1)

- April 2019 (2)

- March 2019 (3)

- February 2019 (4)

- December 2018 (1)

- November 2018 (1)

- September 2018 (2)

- August 2018 (1)

- July 2018 (1)

- May 2018 (3)

- April 2018 (1)

- February 2018 (3)

- January 2018 (2)

- December 2017 (3)

- November 2017 (1)

- October 2017 (2)

- September 2017 (4)

- August 2017 (1)

- July 2017 (2)

- June 2017 (2)

- May 2017 (3)

- April 2017 (3)