Share this

Did You Know Therser UK Offer A Full Turnkey Solution For Your Next Project?

by Therser UK on 11-Jul-2023 12:29:46

At Therser UK we offer a full Turnkey Solution for your next project.

Over the last few decades, we have transformed our offerings into a fully in-house service. By maintaining complete control over your project, we ensure the highest level of quality and efficiency. Within our organization, dedicated teams in each department collaborate closely with you, fostering a true partnership.

Why choose Therser UK

Having delivered hundreds of kilns across the globe, we take pride in our exceptional management team that boasts hundreds of years of combined experience in successful UK-based Kiln and Furnace businesses. Our commitment to excellence drives us to be the leading experts in our field. When you choose us, you'll receive a comprehensive turnkey solution for your next project, encompassing every aspect from the initial weld to on-site installation.

At Therser UK, we stay at the forefront of technology, utilizing cutting-edge advancements and employing the highest quality materials and components. Prior to shipment, all our kilns undergo rigorous testing, and once installed, our engineers provide remote access for troubleshooting, ensuring seamless operation.

Below is a full breakdown of our capabilities across our 4 locations across the UK.

What does this mean for our customers?

- Direct Communication to our team

- Customization and Flexibility

- Quality Control

- Faster Iterations and Time-to-Market

- Intellectual Property Protection

- Long-Term Support

- Cost Efficiency

- Confidentiality and Security

What can our team offer and what services do we provide?

- Thermal process review and concept development

- Technical proposal and formal quotation

- Pre engineering to full engineering

- Stress analysis

- Computational Fluid Dynamics

- Heat up and heat transfer thermal analysis

- 3D modelling

- Welding and Fabrication of all the project

- Alloy fabrications

- Fibre lining

- Full refractory solutions

- Energy efficient Combustion systems

- Electric element heating systems

- Fully bespoke Automation systems

- Fully designed saggar handling systems

- Virtual reality tours of you project

- 3 in-house electrically fired test kilns, with process gas options

- Kiln calibration

- CAD drawing and design

- Project managed

- Test firings of your product

- Inhouse gas combustion training facility

- Inhouse PLC programming

- Inhouse panel building

- Hydrogen demonstrator

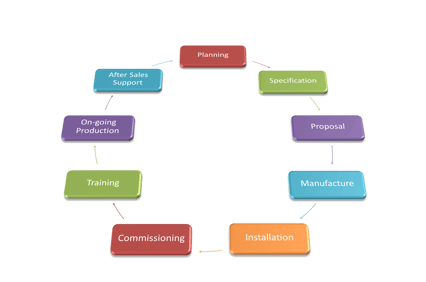

Our Partnership Circle

Support

- Kiln relocations

- Kiln and furnace refurbishments, upgrades and spare parts

- Burner / combustion system upgrades

- Gas to electric conversions

- Brickwork repair

- Servicing

- On-site training

- Remote support with technical knowledge

- Safety reviews and upgrades

- Energy efficiency reviews and upgrades

This is our Engineering, Fabrication and Assembly facility based in Stoke on Trent.

.jpg?width=458&height=214&name=Meir%2027-06-23%20%20(13).jpg)

This is our Head Office and R&D facility for customer test firing. We can the option to fire with different sized kilns all with the option of process gases of your choice. We can follow most firing curves that are required.

Another one of our assembly halls based in Stoke on Trent

This is our Furnace Engineering and Alloy Fabrication division based in Tipton

Contact Us: For quotes, questions, and sales inquiries, please reach out to our dedicated technical sales team:

- Phone: +44 (0) 1782 824 453

- Email: sales@therseruk.com

- Social Media: Find us on Facebook Twitter Linkedin

- https://www.therseruk.com/

Share this

- Company News (90)

- Battery Materials (41)

- kiln (37)

- fabrication (29)

- Alloy (27)

- Furnace (27)

- Welding (16)

- Industrial Kilns (15)

- Battery (13)

- Ceramic Kilns (13)

- Processes (13)

- alloy fabrication (13)

- Shuttle Kilns (12)

- RTO’s (11)

- Vacancies (11)

- Hydrogen (10)

- Therser UK (9)

- Tunnel Kiln (9)

- Refractory (8)

- Therser (8)

- Wellman Furnaces (8)

- Brickwork (7)

- Case Studies (7)

- Afterburners (6)

- Fibre Lining (6)

- electric (6)

- Almor Wellman (5)

- thermal engineers (5)

- Biochar (4)

- Exhibition (4)

- Pyrolysis (4)

- Servicing (4)

- Spares (4)

- heat treatment (4)

- History (3)

- Ceramics Uk (2)

- Combustion Control Upgrades (2)

- Nitrogen (2)

- Temperature Control Rings (2)

- gas (2)

- Certificates (1)

- Instrumentation (1)

- MMC (1)

- RHK (1)

- Roller Hearth Kiln (1)

- Test Trials (1)

- aerospace (1)

- analyser (1)

- elec (1)

- oxygen (1)

- vans (1)

- September 2025 (2)

- May 2025 (2)

- March 2025 (1)

- February 2025 (2)

- January 2025 (5)

- December 2024 (5)

- November 2024 (7)

- October 2024 (5)

- September 2024 (4)

- August 2024 (14)

- July 2024 (13)

- June 2024 (2)

- May 2024 (5)

- April 2024 (13)

- March 2024 (8)

- February 2024 (12)

- January 2024 (14)

- December 2023 (6)

- November 2023 (12)

- October 2023 (24)

- September 2023 (11)

- August 2023 (11)

- July 2023 (9)

- June 2023 (15)

- May 2023 (53)

- April 2023 (5)

- March 2023 (6)

- February 2023 (7)

- January 2023 (3)

- December 2022 (8)

- November 2022 (5)

- October 2022 (11)

- September 2022 (1)

- August 2022 (2)

- July 2022 (1)

- June 2022 (2)

- May 2022 (1)

- March 2022 (1)

- February 2022 (1)

- January 2022 (1)

- December 2021 (3)

- October 2021 (1)

- August 2021 (1)

- June 2021 (1)

- May 2021 (4)

- April 2021 (2)

- March 2021 (4)

- February 2021 (2)

- December 2020 (3)

- November 2020 (1)

- September 2020 (3)

- May 2020 (1)

- April 2020 (2)

- March 2020 (1)

- January 2020 (1)

- December 2019 (1)

- July 2019 (2)

- June 2019 (1)

- April 2019 (2)

- March 2019 (3)

- February 2019 (4)

- December 2018 (1)

- November 2018 (1)

- September 2018 (2)

- August 2018 (1)

- July 2018 (1)

- May 2018 (3)

- April 2018 (1)

- February 2018 (3)

- January 2018 (2)

- December 2017 (3)

- November 2017 (1)

- October 2017 (2)

- September 2017 (4)

- August 2017 (1)

- July 2017 (2)

- June 2017 (2)

- May 2017 (3)

- April 2017 (3)